What is TIG welding?

TIG – or tungsten inert gas – welding is versatile form of welding which uses a tungsten electrode surrounded by a pocket or flow of inert gas to provide an electric arc to the material. TIG welding is best used for making complex welds, and can be utilized on a wide variety of materials – even two different metals! Inert gases such as argon are called inert because of their inability to react with other materials. A flow of inert gas over the electrode pushes regular air away from the weld area. This keeps oxygen away from the weld while it cools, keeping the material from oxidizing at the weld site. Different mixtures of gases are used for different metals depending on their oxidation properties.

Preparing to TIG weld

- Make sure your welder is set up for the proper materials and conditions. Each material is different, so to get a better idea take a look at this welding calculator.

- Grind your electrode to a point (DC) or ball (AC) – much like lightning tends to strike tall, pointed skyscrapers, a pointed electrode will make it easier to guide the arc keeping it from moving around on the electrode.

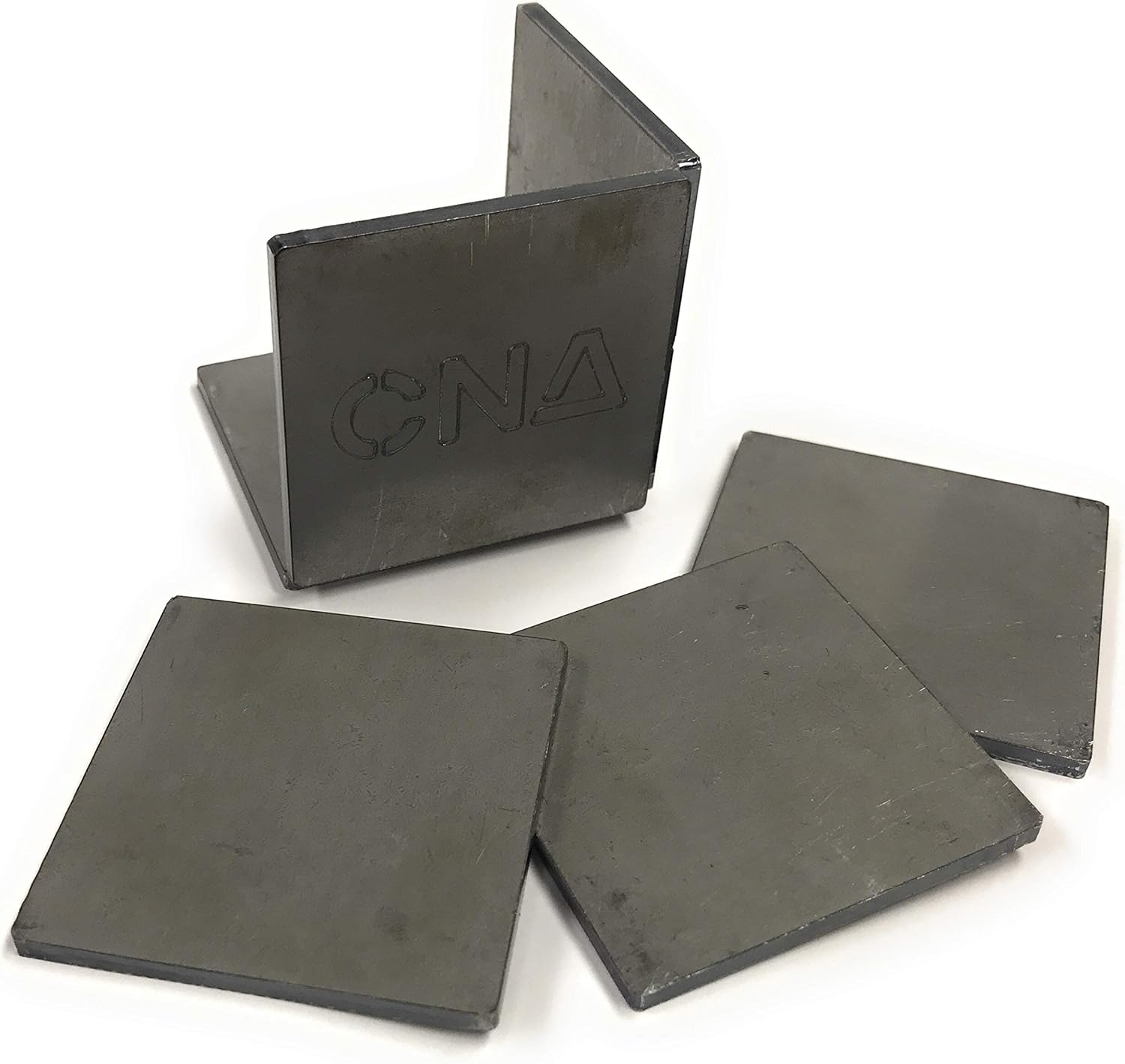

- Make sure you have a large metal surface to weld on. Most have a welding table specifically for this purpose, but a large piece of sheet metal will do in a pinch.

- Prepare your materials: for the best welds, clean the weld rods with acetone or isopropyl alcohol, wire brush the surface being welded (try to keep a separate brush used only for aluminum vs your other materials), and clamp down your work to keep it in place during the weld.

- SAFETY FIRST

- Always wear thick, non-conductive (heat and electricity) gloves

- Always wear a welding helmet – the arc will make you go blind if not looking through a special visor.

- Wear the proper clothing. TIG arcs can give you burns similar to sunburn (not to mention things get pretty hot, contact will also burn you), so always wear long sleeves and pants as well as closed-toed shoes.

TIG Welding Tips

- Use tack welds to your advantage. Heat the work (but not so much that it warps) and apply small beads of weld at intervals. Once cooled, these should hold your two pieces of work together and get the clamps out of the way for the main weld.

- Alternate sides. Hot metal expands and warps (and on the same note welds shrink as they cool) – so to minimize any warping, try to alternate your welds on different sides of the work.

- Make sure you are holding and using the rod correctly – different materials have different techniques (e.g. in Aluminum the electrode should move towards the weld rod but the opposite is the case in steel.)